Description

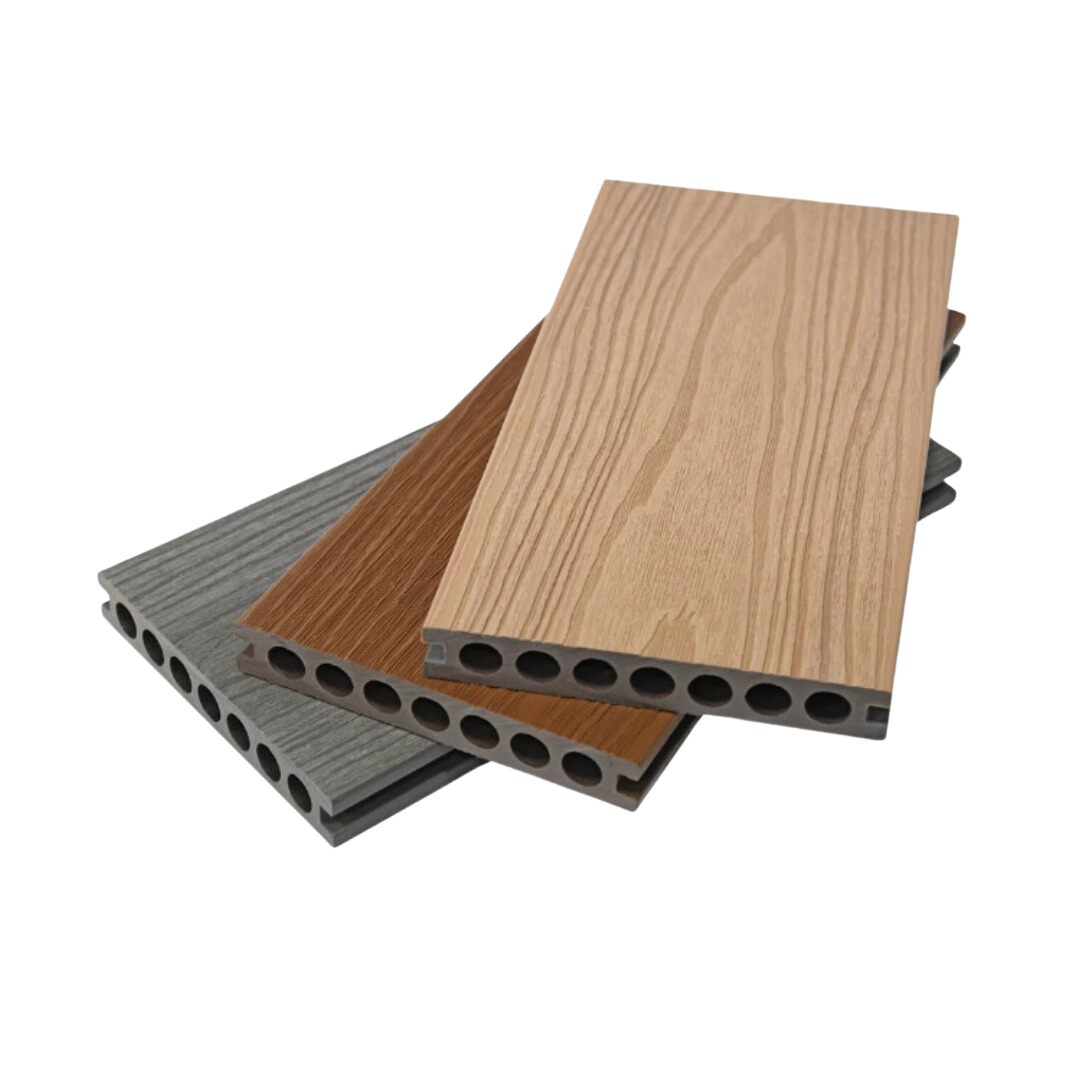

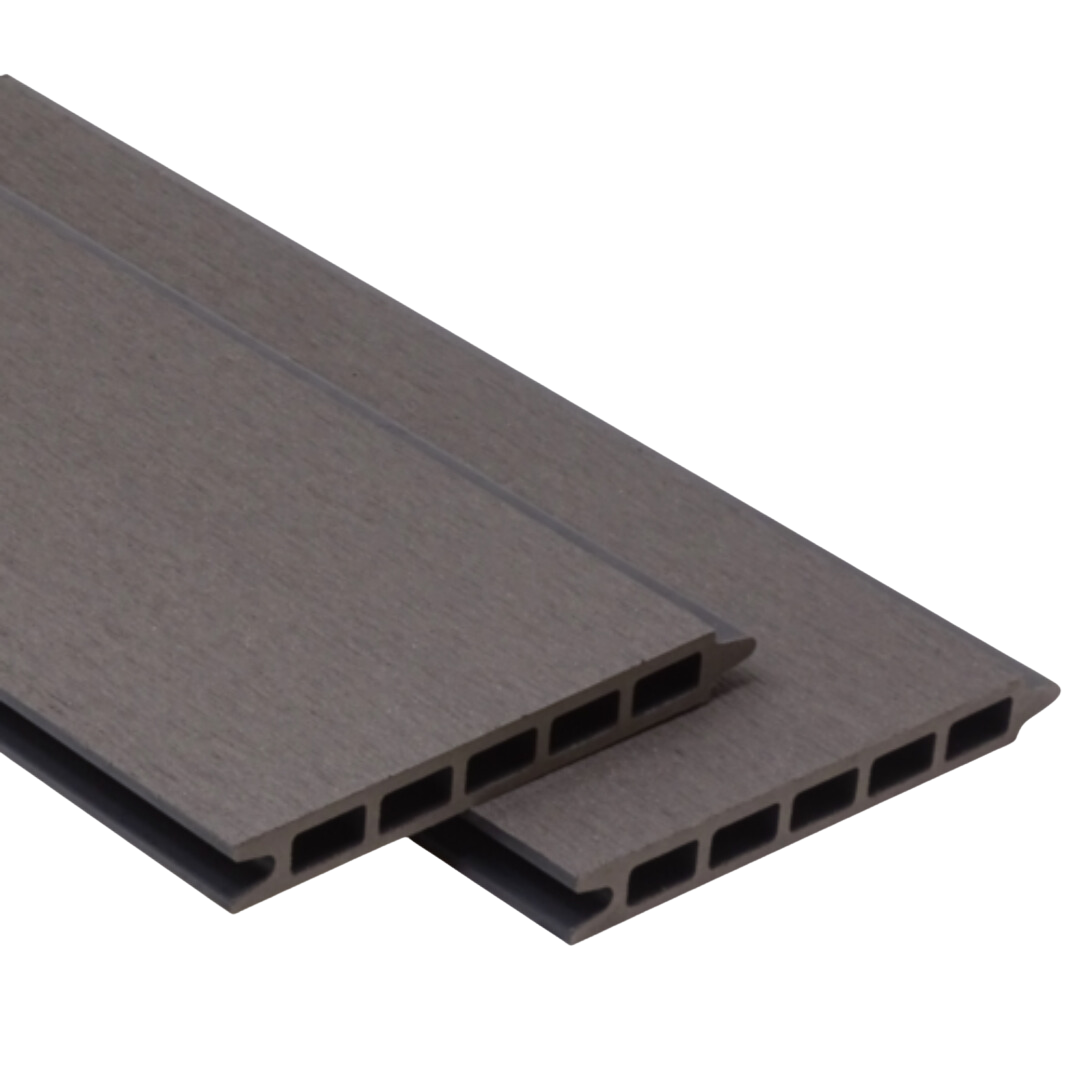

Wood-plastic composites (Wood-Plastic Composites, WPC) is a new type of composite material that has been booming in indoor and outdoor decoration industry in recent years. This is a new type of material mixed with various raw materials such as PVC, PE and wood flour.

Specifications

| Product name | WPC Well-matched Interior Decorative Trim |

| Model | YLA7030 |

| Size(Width&Thickness) | 40*50mm |

| Lenth | 2.8m, 2.95m,3.0m or Customized |

| Materila | Wood Pastic Composit |

| Color | Customized |

| Flame- retardant level | B1 (Highest level on the WPC Product) |

| Water absorption | Less than 1% |

| Payment term | 30%T/T deposited,balance 70%T/T paid before shipment |

| Application | Commercial or domestic interior decoration |

| Installation | Quick&Easy Installation |

| MOQ | 500 meters |

| Brand name | Ideawood |

| Package | Professional Export Carton, Pallet or Customized |

| Delivery period | Within 10 days |

| After sale service | Return and Replacement |

| Warranty | 10 years |

Features

1) Good processing performance

Wood-plastic composites contain plastics and fibers, so they have processing

properties similar to wood. They can be sawed, nailed, and planed with

woodworking tools, and their nail-holding power is significantly better than

other synthetic materials. Mechanical properties are superior to wood materials.

The nail holding power is generally 3 times that of wood and 5 times that of

particleboard.

2) Good strength properties

Wood-plastic composites contain plastic, so they have a better modulus of

elasticity. In addition, because it contains fibers and is fully mixed with

plastic, it has physical and mechanical properties equivalent to hardwood such

as compression and bending resistance, and its durability is significantly

better than ordinary wood materials. The surface hardness is high, generally 2-5

times that of wood.

3) Water resistance, corrosion resistance, long service life

Compared with wood, wood-plastic materials and their products are resistant

to strong acid and alkali, water and corrosion, and do not reproduce bacteria,

are not easy to be eaten by insects, and do not grow fungi. Long service life,

up to 50 years or more.

4) Excellent adjustable performance

Through additives, plastics can undergo changes such as polymerization,

foaming, curing, and modification, thereby changing the characteristics of

wood-plastic materials such as density and strength, and can also meet special

requirements such as anti-aging, anti-static, and flame-retardant.

5) Light stability&coloring property

It has ultraviolet light stability and good coloring property.

6) Eco friendly

Its biggest advantage is turning waste into treasure, and it can be 100%

recycled and reproduced. It can be decomposed and will not cause “white

pollution”. It is a real green product.

7) Extensive sources of raw materials

The plastic raw material for the production of wood-plastic composite

materials is mainly high-density polyethylene or polypropylene, and the wood

fiber can be wood flour, grain bran or wood fiber, and a small amount of

additives and other processing aids are also required.

8) Support OEM

It can be made into any shape and size as required.